Advantages of Ultra High Speed Laser Cladding over Traditional Laser Cladding Processes

Laser cladding, as an important remanufacturing technology, has multiple advantages such as high quality, efficiency, energy saving, material saving, environmental protection, and innovation. Traditional laser cladding refers to the laser source using YAG laser, CO2 laser, and semiconductor direct output or fiber output semiconductor laser for cladding. Compared to semiconductor lasers, YAG lasers and CO2 lasers have higher energy consumption, frequent maintenance, time-consuming repairs, and lower efficiency. In the first two years, semiconductor direct output lasers were widely used in China. In addition to foreign brands, 2-3 light source suppliers have also emerged in China, mainly used for repairing and processing equipment in the coal mining, power, and petroleum industries. The stability of semiconductor lasers is an important factor limiting their widespread promotion in the laser cladding industry. Compared to the first two types of lasers, semiconductor lasers have a shorter continuous output time and higher maintenance costs in the later stage.

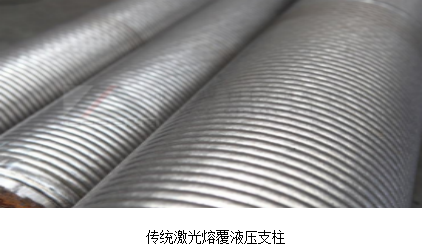

Traditional laser cladding uses prefabrication or synchronous powder feeding methods. Prefabrication is the process of placing the cladding material in the cladding area on the surface of the substrate, and then using laser beam irradiation to scan and melt it. The cladding material is added in the form of powder, wire, and plate, with powder being the most commonly used form. Synchronous laser cladding is the process of directly feeding the cladding material into the laser beam, allowing both feeding and cladding to be completed simultaneously. The cladding material is mainly fed in the form of powder, and some are also fed synchronously using wire or sheet metal. Traditional laser cladding has a low rate, poor surface flatness of the cladding layer, and a thicker cladding layer. Usually, secondary processing is required for grinding after the cladding is completed, which consumes materials and time.

Compared with traditional conventional cladding, ultra high speed laser cladding has a cladding speed that is tens or even hundreds of times faster. The ultra high speed laser cladding technology has the characteristics of being flat, thin, and fast.

Flat, refers to a flat surface cladding layer, and high-speed laser cladding generally adopts synchronous powder feeding method. The relative movement speed between the laser source and the substrate surface is fast, and the cladding surface is very flat with high smoothness.

Thin, the surface thickness of the ZKZM high-speed laser cladding layer can achieve a thickness of 0.03-0.5mm, without the need for excessive post-processing

Fast, the normal laser cladding speed is 0.2-2 meters per minute, and the high-speed laser cladding technology of ZKZM can reach 20-200 meters per minute.

In addition, ultra high speed laser cladding also has multiple advantages such as high metallurgical quality of cladding coatings, low dilution rate, and small deformation, providing important technical and basic equipment support for the rapid development of China's remanufacturing industry in the later stage.