ZKZM Leads the Development of Laser Additive Manufacturing Industry

Technology In the wave of rapid scientific and technological development, laser technology has become the core driving force of advanced manufacturing, profoundly reshaping the production patterns of various industries. Among them, high - speed laser cladding technology, with its remarkable advantages, has become a key technology in the field of material surface modification and repair and has attracted much attention.

1. High - speed Laser Cladding Technology:

An Innovative Force in Advanced Manufacturing High - speed laser cladding technology uses a high - energy - density laser beam as a heat source to precisely clad metal powder (specially made metal alloy powder) onto the surface of a metal substrate. Under the action of laser energy, the powder is rapidly melted and solidified, forming a coating on the substrate surface that is metallurgically bonded to the substrate, dense, uniform, and with a controllable thickness. This coating can not only significantly improve the wear resistance, corrosion resistance, high - temperature resistance, and oxidation resistance of workpieces, but also repair the dimensions of worn or workpieces, greatly enhancing the performance of workpieces and effectively extending their service life.

Compared with traditional technologies such as TIG arc additive manufacturing, ultra - high - speed flame spraying, plasma spraying, and hard chromium electroplating, high - speed laser cladding technology has obvious advantages: the single - layer coating thickness is thin, enabling fine surface treatment; the metallurgical bond ensures a high - strength bond between the coating and the substrate; the heat - affected zone is small, minimizing the impact on the properties of the substrate material; the surface flatness is high, reducing subsequent processing steps; and it is pollution - free, in line with the concept of modern green manufacturing. It is truly an advanced surface modification technology.

ZKZM Laser Technology Co., Ltd. was incubated from Xi'an Institute of Optics and Precision Mechanics, Chinese Academy of Sciences in 2012. Since its birth, it has shouldered the mission of scientific and technological innovation. The company's founder, Duan Kailiang, a Ph.D. in Optics from Sichuan University, a researcher at Xi'an Institute of Optics and Precision Mechanics of the Chinese Academy of Sciences, and an advanced individual of the "11th Five - Year Plan" of the National 863 Program, led the team to successfully launch China's first kilowatt - class industrial fiber laser in 2013, laying a solid foundation for the development of China's laser industry. Since its establishment, ZKZM has adhered to the path of independent innovation and continued to delve into the field of high - power laser industrial applications. It has applied for more than 50 patents in total. These patent achievements are a powerful testament to the company's technical strength and an important force in promoting the technological progress of the industry.

High - speed laser cladding is a new technology that emerged at the end of 2017. In 2018, ZKZM successfully developed and launched China's first high - speed laser cladding equipment. After years of development, high - speed laser cladding technology has matured in China, with dozens of participating enterprises. However, most of their power levels are below 10,000 watts. At power levels above 10,000 watts, the durability and reliability of the key component, the high - speed laser cladding head, decrease, and its service life is shortened, making it unable to meet the requirements of industrial applications.

Since 2022, ZKZM has exclusively launched 10,000 - watt high - speed laser cladding equipment. Linzhou Heavy Machinery (stock code: 002535) has used more than a dozen 10 - KW high - speed laser cladding equipment of ZKZM for the laser cladding of the inner and outer walls of oil cylinder hydraulic supports. The 10,000 - watt high - speed equipment has advantages such as high efficiency, strong coating adhesion, and easy crack control compared with 6000 - W high - speed equipment.

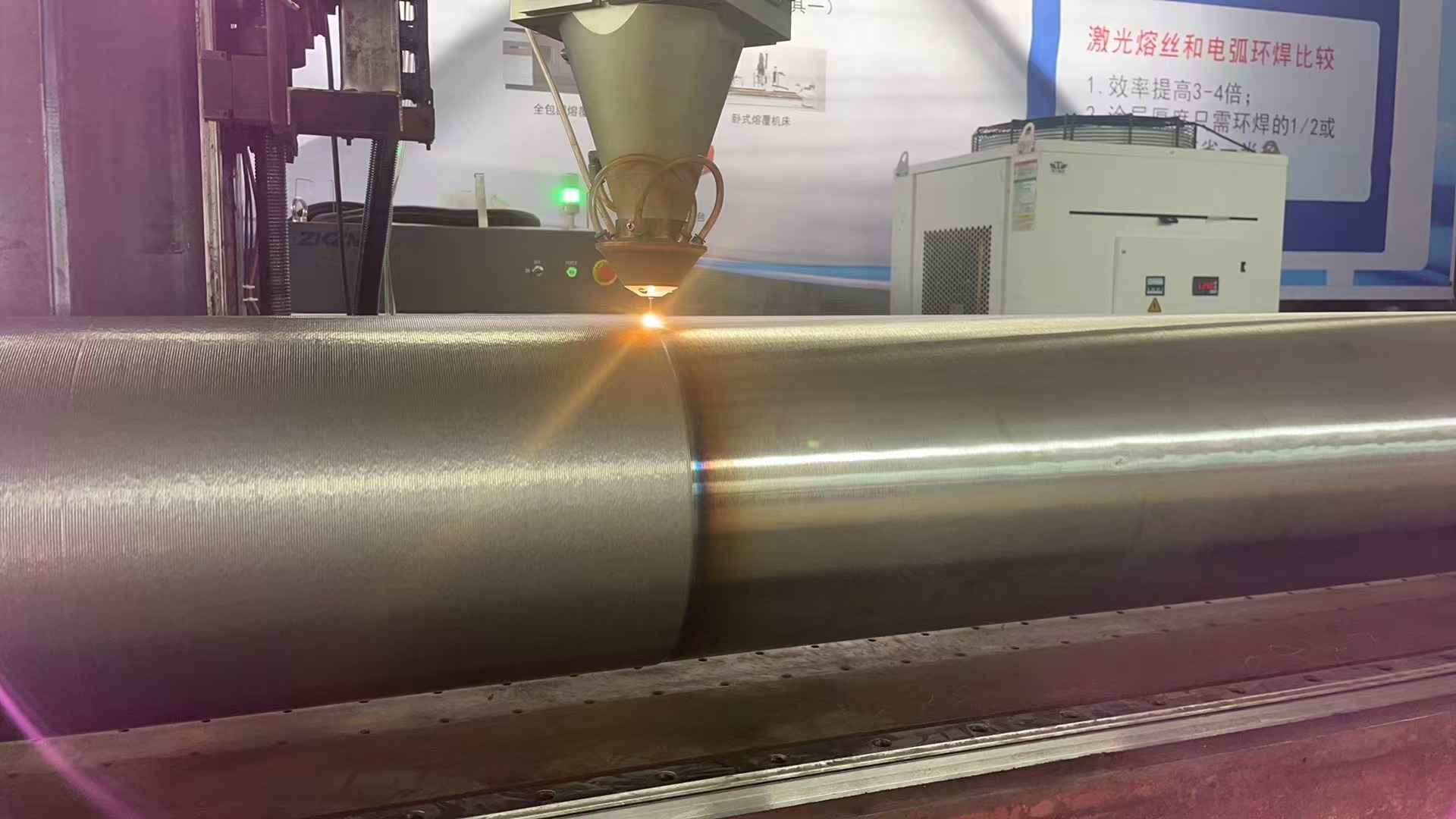

However, in the metallurgical industry, the surfaces of heavy - duty rolls often require thick, high - hardness, and high - wear - resistant coatings, and 10KW cladding equipment is still difficult to meet the requirements. Therefore, ZKZM launched 15 KW and 20KW high - speed laser cladding equipment in 2025. In addition, currently, all high - speed laser cladding equipment on the market is powder melting equipment, and there is no industrial grade high power wire melting equipment. Germany and some domestic manufacturers have developed wire melting equipment below 6000 W, but the cladding efficiency and equipment reliability are far from reaching the industrial level. The wire applications on the market all use arc technology.

Therefore, after years of technical breakthroughs, ZKZM launched a 10 KW wire - melting equipment in the second half of 2024, filling a gap in the industry. In 2025, a 15 KW wire melting equipment was launched, establishing the international leading position of domestic equipment technology. In summary, ZKZM' s 10KW class powder melting equipment and 10KW class wire - melting equipment are both at the international leading level. Especially the 10KW wire - melting equipment can be used not only for laser cladding and laser surfacing but also for laser welding and laser 3D printing. ZKZM will play a huge role in promoting the development of the additive (re) manufacturing industry technology in China and even globally.