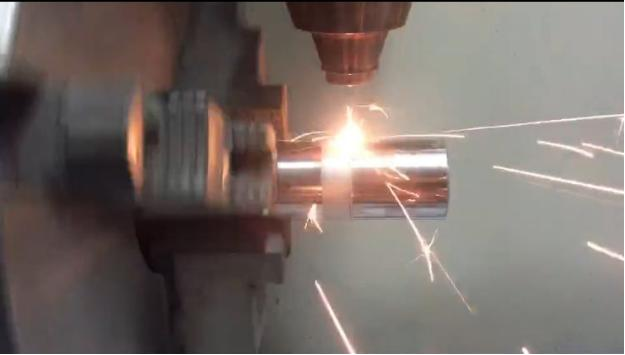

How to Select High - Speed Laser Cladding Equipment with Different Powers

The power selection of high - speed laser cladding equipment directly affects aspects such as the subsequent cladding effect, processing efficiency, and cost. Currently, the powers of high - speed laser cladding equipment in China mainly focus on 6000W, 10000W, and 15000W. Many users don't know how to choose a more suitable cladding machine for their needs before purchasing the equipment. This article mainly conducts a comparative analysis of the parameters and performances of 6000W and 10000 - watt laser cladding machines, aiming to help users select a more suitable high - speed laser cladding equipment when making a purchase.

1. Comparison of Technical Parameters

Power The power of 10000 - watt high - speed laser cladding equipment is usually above 10000W. Currently, 10000 - watt high - speed laser cladding machines in China mainly include 10000W, 12000W, and 15000W models. While the 6000 - watt equipment has a laser power of 6000W when operating at full power.

Cladding Efficiency The principle of laser cladding is the thermal accumulation of laser energy. Therefore, a higher laser power means a higher energy density and a faster processing speed. Under the same processing conditions, the cladding efficiency of a 12000W high - speed laser cladding machine is twice that of a 6000W machine.

Cladding Processing Objects 10000 - watt high - speed laser cladding has a wider processing range. For example, when processing thick coatings or materials with high melting points and hardness, low - power (≤6000W) laser cladding may face difficulties (such as the need for high - temperature pre - heating of the substrate or poor cladding quality with a low yield rate), while 10000 - watt equipment can complete the cladding efficiently, easily, and with high quality (without the need for substrate pre - heating, etc.).

Powder Utilization Rate The powder utilization rate of 6000 - watt equipment is approximately 85%. Currently, there are two types of 10000 - watt high - speed laser cladding technologies. One is circular - spot annular powder feeding, with a powder utilization rate of 85%. The other is multi - beam central powder feeding technology, with a powder utilization rate of over 90%.

Equipment Stability Currently, industrial - grade domestic lasers have reached the 100KW level, and the stability of lasers has been fully verified in the market. The stability of high - speed laser cladding equipment mainly depends on the stability of the laser cladding head. The laser cladding head with an annular powder - feeding method is relatively stable under low - power (≤6000W) conditions. Currently, 6000W high - speed laser cladding machines on the market are completely mature and suitable for high - intensity industrial production applications. However, if a 10000 - watt high - speed laser cladding equipment is equipped with a cladding head with an annular powder - feeding structure, due to the high laser power, problems such as powder blockage, powder adhesion, and powder - induced head deformation may occur, resulting in poor equipment stability and safety during use. In contrast, the cladding head with a central powder - feeding structure solves the design defects of the annular powder - feeding method mentioned above. Therefore, in the industrial application market, stable and mature 10000 - watt high - speed laser cladding equipment generally adopts a central powder - feeding structure design, that is, a light - enveloping - powder structure. In addition, there are some 10000 - watt wide - spot/square - spot cladding machines on the market. These cladding machines belong to ordinary laser cladding and are not within the scope of high - speed laser cladding. For performance analysis and comparison of such machines, please refer to other articles, and they will not be compared or elaborated here.

Heat Input and Equipment Volume Due to the higher power, 10000 - watt equipment has a relatively high spot power density and a larger heat input. When processing some thin and small workpieces, the power needs to be reduced to an appropriate range. 10000 - watt laser cladding machines are larger in volume and occupy more space compared to 6000W equipment (with a difference of approximately 2 square meters in total floor area).

Comparison of Application Fields Based on the above comparison of the technical parameters of high - speed laser cladding machines with different powers, it is recommended that users consider the following aspects when selecting a high - speed laser cladding machine with an appropriate power.

6000W high-speed laser cladding | 10000W high-speed laser cladding | |

Equipment Purchase Cost | Low | High |

Applicable Processing Fields | Small and medium - sized thin - walled components(especially suitable for small machining factories) | Large - scale components, high - melting - point, high - hardness wear - resistant coatings, thick coatings, and mass processing (such as in the iron and steel metallurgy, breaker hammer processing fields, etc.) |

Equipment Stability | Good stability| | Annular powder feeding (poor stability) Central powder feeding (good stability) |

Service Life | 5 years (when the power decays to 3000W, the efficiency is too low) | ≥10 years (with a large power decay margin) |

Maintenance Cost | Low | Annular powder feeding (high)Central powder feeding (low) |

Conclusions and Suggestions Both 10000 - watt high - speed laser cladding equipment and 6000 - watt equipment have their respective applicable scenarios, advantages, and disadvantages. When choosing equipment, enterprises should conduct a comprehensive assessment based on their own production requirements, budget, and technical capabilities. It is believed that in the next few years, with the intensification of market competition, the reduction in the cost of upstream laser equipment, and the further maturity of laser technology, high - speed laser cladding equipment will be widely used in more fields and become an important force in promoting the development of China's laser re manufacturing industry.